Industries manufactures and exports Precision machined Parts and Components by milling, turning, forging, casting and stamping from various metals.

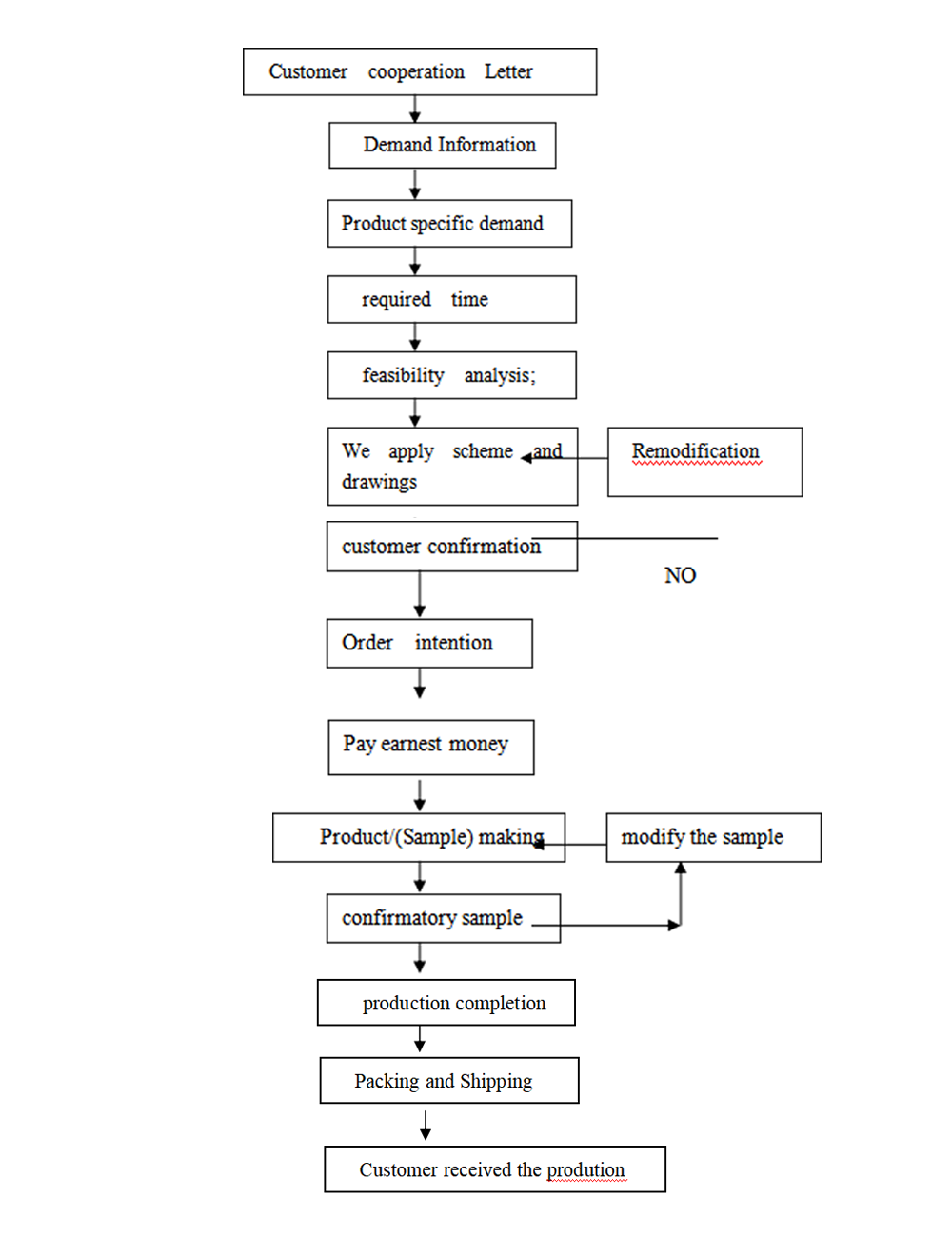

We are expertise in customized manufacturing and subcontracting for domestic and overseas clients. In fact, customized manufacturing is more than 85% turnover of our company

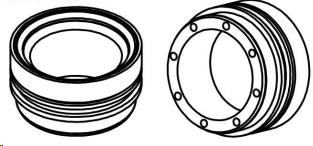

means Original Equipment Manufacturer,in the OEM process we won’t design drawings for the customer,we just product according to the customer’s drawings and couldn’t make the same production for other customers.it’s process contains:Customer orders and drawings,confirm drawings and quotations,sign back,down payment,product,inspecting,packing and transportation.Compared to ODM, OEM has fewer steps in drawing design and sample production.

Quality always comes first during the production in valve world.

•ISO 10204: 3.1/3.2 material certification

•Visual inspectioin

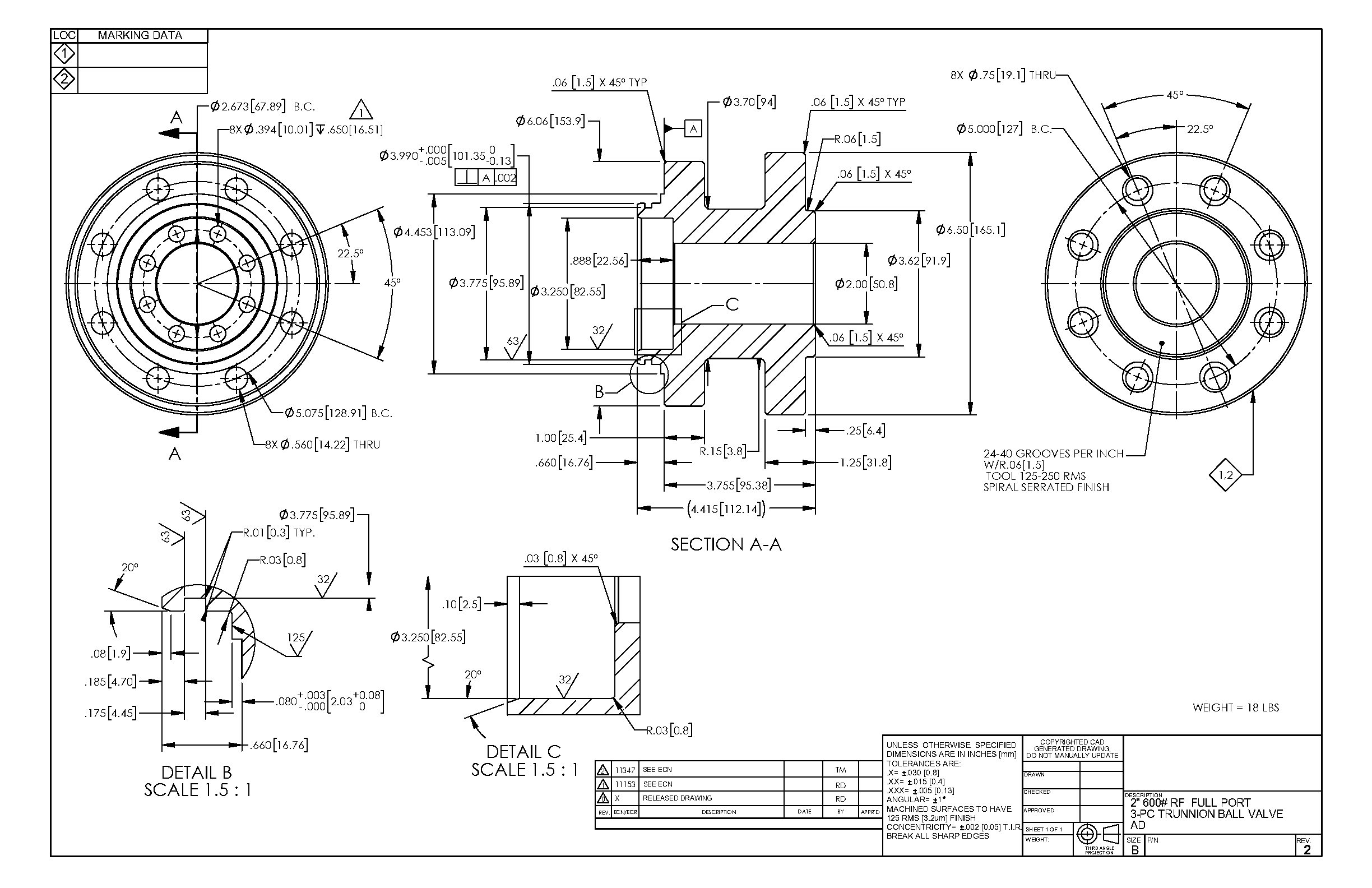

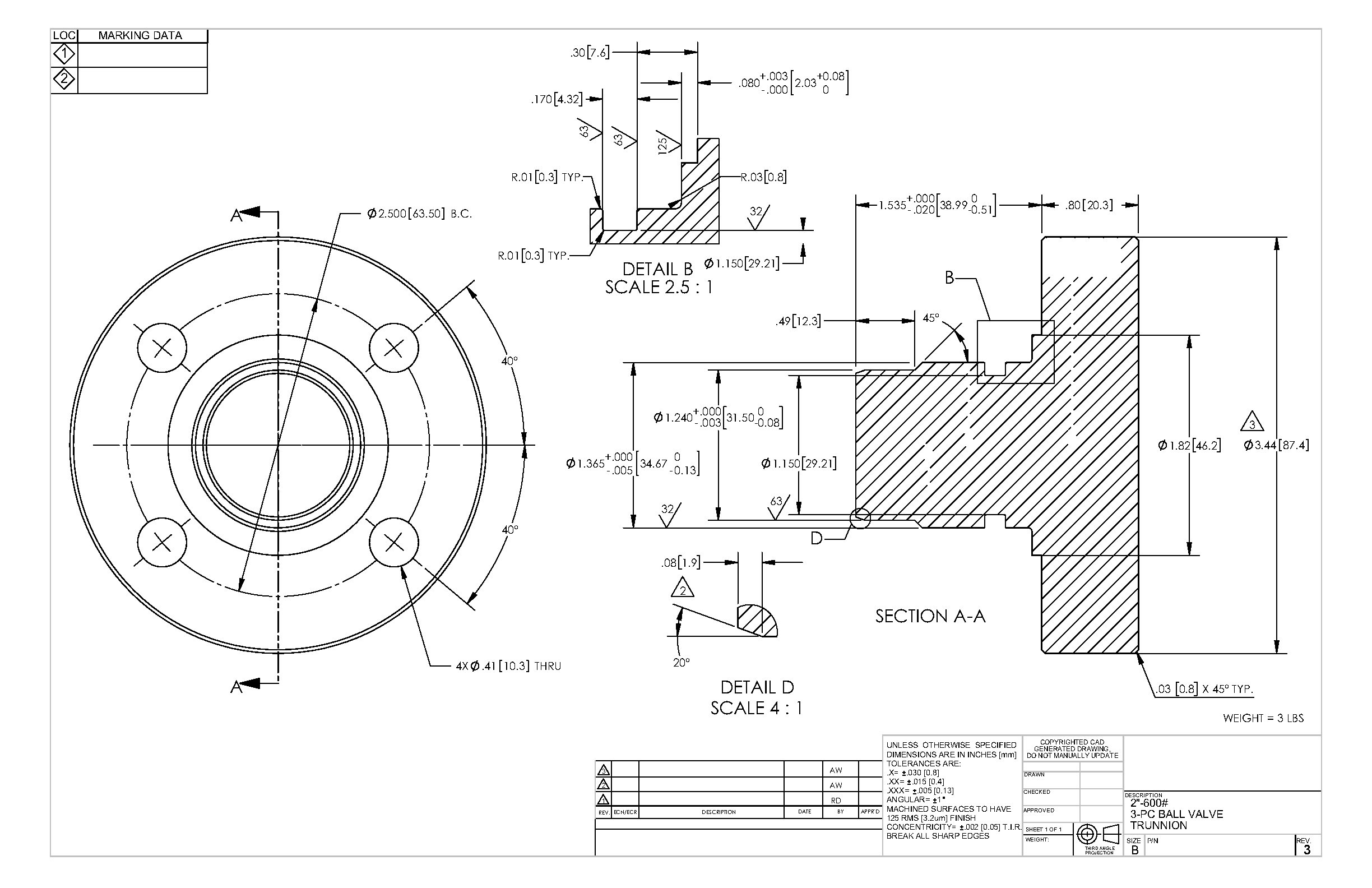

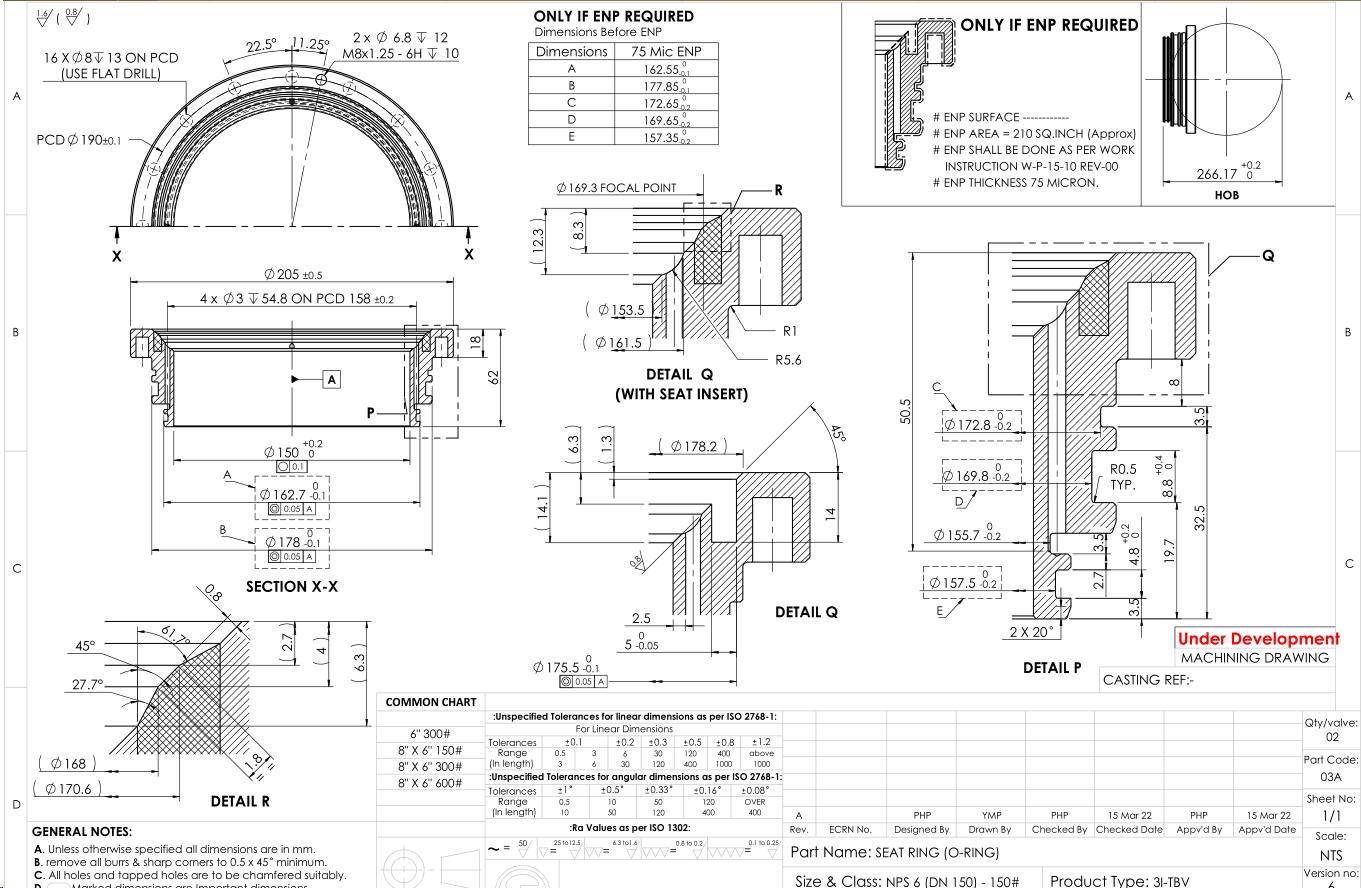

•Dimension Inspection

•Chemical Analysis & PMI inspection

•Mechanical Examination

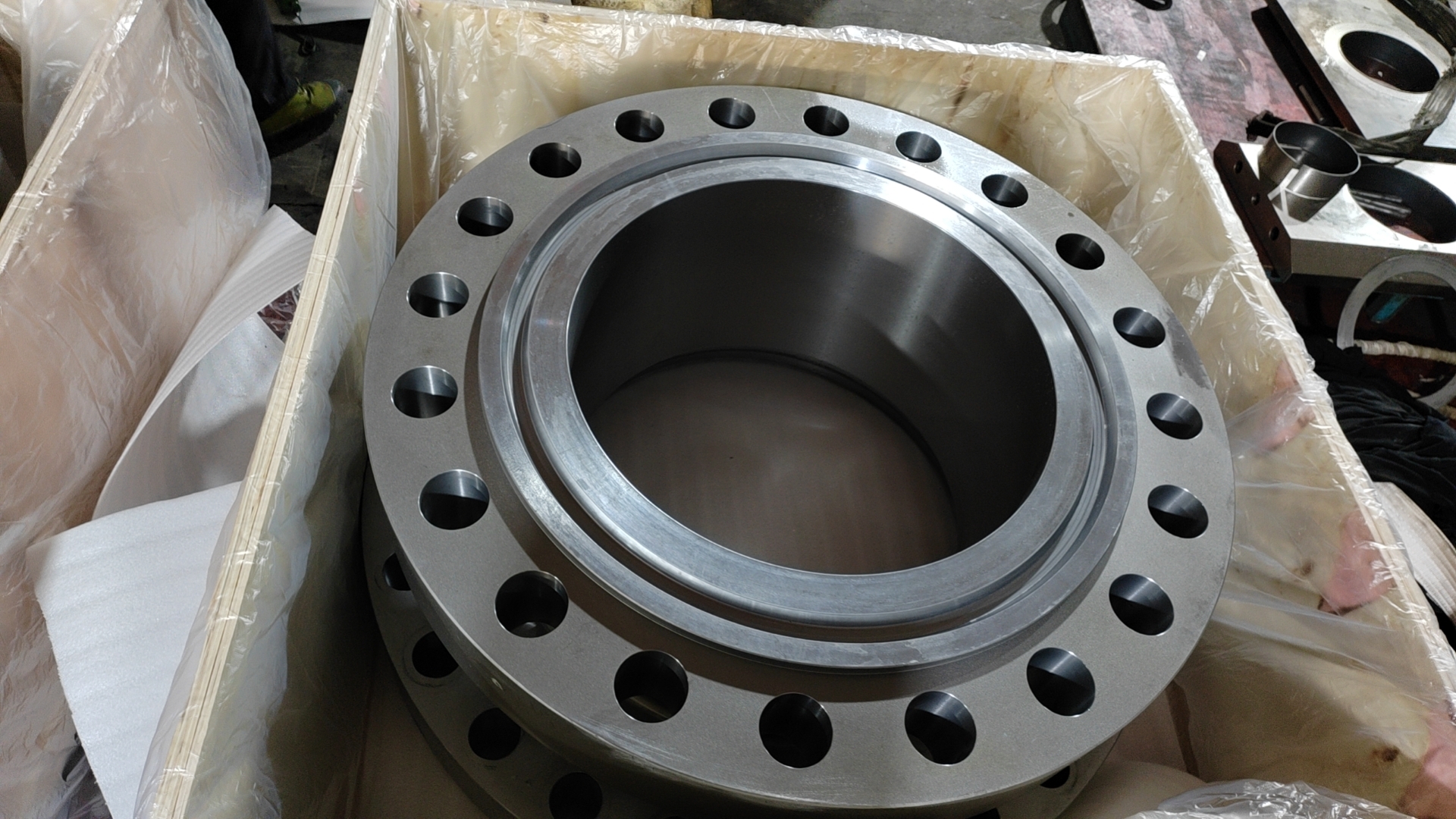

•Quality inspection in machining & assembling

•NDT testing

After the product completed,we’ll send you the photo or video of the production if you need,then we’ll pack and transport the production to your designated place.